The decision to pack up and tackle life on the road came together fairly quickly, and very soon afterward, the reality of having to acquire a caravan suitable for long-term family living loomed over us - but that’s another story completely. The bigger issue (at least for Nate) was choosing a vehicle that would not only fit a family of four comfortably, but also tow a full-sized van, handle outback conditions, chew through thousands of kilometres of corrugations, dust, mud, sand, river crossings, and ultimately get us in and out of the remote locations we wanted to explore. Nate also wanted something he could fix himself on the side of the road if he needed to knowing spare parts would be available anywhere in the country.

After doing some research and talking to other experienced travellers, he came to the conclusion that the car he wanted didn’t really exist, not directly, at least, and definitely not within our budget. What followed probably seemed like a nightmare for anyone looking in, although I’m convinced Nate loved every minute of it.

He found a cheap and fairly clean 105 Series Landcruiser in Adelaide for only $3,000, so he jumped on a plane to go and collect it. However, after inspecting it in person, he wisely opted not to attempt the 2,000km solo trek home in it. The Cruiser ended up on the back of a truck, and Nate back on a plane, it was the perfect first piece the car build puzzle.

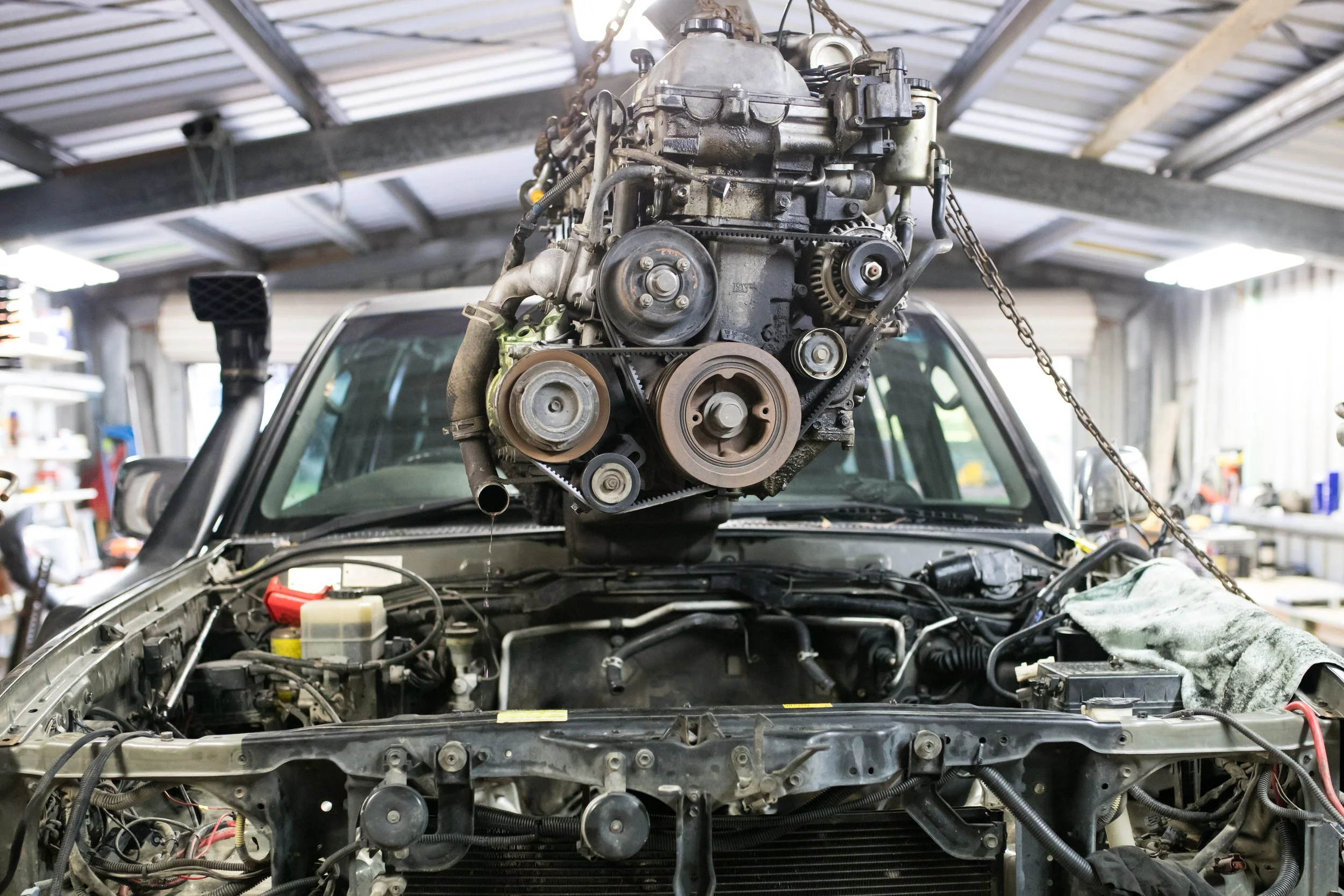

Once the chassis and cab had been secured, Nate started the hunt for the motor. The 1HD-FTE engine from the 100 Series Landcruiser is a relatively straightforward swap into a 105 Series, but finding a good donor proved to be a challenge. Eventually, a private sale popped up, a low-kilometre 100 Series not too far from home, and he jumped on it.

Although the process of swapping out the 6-cylinder petrol motor for the factory turbo diesel was not overly complicated, Nate had inadvertently purchased a Kakadu facelift 100 Series with full leather interior, rear aircon, and a number of other practical and cosmetic enhancements, all of which somehow made their way into the final build. The aircon cooled centre console even found its way into the car for a short time.

The wiring alone was monumental. The difference between a pre-2000 105 and a 2004 100 series is night and day. The looms weren’t even remotely compatible. Nate had to strip the vehicles back to their bare shells and replace every length of wire and connector to make it work. Fuse boxes, control modules, door wiring, dash harnesses. the works, Electric windows, central locking, leather seats, rear aircon—all retrofitted into the body.

Nate also swapped out the petrol fuel tanks, retro fitted a larger tank from a Prado, as well as the petrol fuel lines for the larger diesel alternatives. The intercooler was upgraded along with the exhaust,. The project might have been a little bigger than he originally anticipated, as he included a handful of other maintenance and performance upgrades along the way including belt, fluids, a 1300Nm clutch and flywheel and anything else that Nate could get to while the motor was out.

He purchased a second hand ARB Bull bar, gave it a fresh coat of 2pack paint and fitted it up along with new winch, and spotlights. The brush bars and side steps were cleaned up from the 100 series and modified to mount to the 105 series chassis. New suspension was fitted to provide an increase in the vehicle’s GVM, and the lift and 35-inch tyres were both engineered and legal.

The rear of the car was fitted out with a 4Point fridge and drawer setup including 200Ah lithium battery, 40L drawer fridge, ARB air compressor, pull out table and plenty of storage. The centre console very soon upgrade to a 17L Engle fridge which proved increasingly valuable on some of those long drives from snacks for the kids to ice cold refreshments.

After a short time and a couple of trips, we decided that we could use a boat while living on the road, and as we knew of a perfect 3.5m Quntrex with a 15hp merc and collapsible trailer for sale it was almost meant to be. Nate had only recently fitted up a roof mounted Rhino Rack and the backbone system doubled as a perfect base to make a customised roof mounted boat loader. Nate wanted the rack to be as slimline and low mounted as possible, but also maintain simple and easy mounting that could be done quickly and effortlessly in camp, at the boat ramp, or even on the beach. The boat loader and setup is also a story for another time.

During our travels we found ourselves in Perth, staying not far from the GTurbo workshop, and as they say; when in Rome… so the little Cruiser went in for a freshen up. With a set of +70 injectors and a Redwheel turbo bolted on, it felt like a completely different car. With plenty of power for the Western Australian sand dunes, the car towed effortlessly, and surprisingly with better fuel economy.

In the end, the car became more than the sum of its parts. What started as a tangle of wires, tools, and big ideas turned into something that’s taken us to places we never could’ve imagined. It’s given us sunrise beach breakfasts, shown us the incredible desert star lit nights, to quiet bush camps, and along a few hairy tracks. It’s carried our family through muddy tracks, rocky climbs, and long stretches of empty road. Building it wasn’t just about creating a capable vehicle; it gave us the freedom to chase memories we’ll carry for a lifetime.